-

Production-Grade Materials

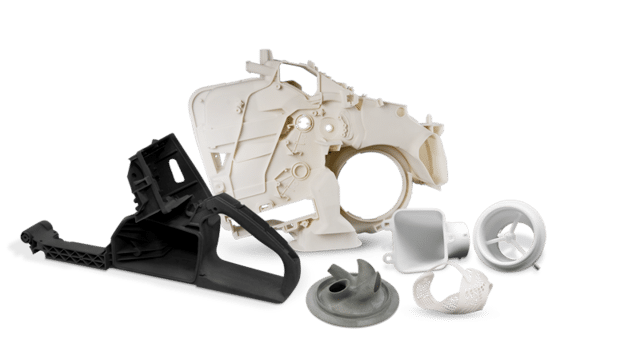

Produce tough, durable parts from a range of DuraForm® ProX production-grade nylon materials that have been optimized, validated and tested to ensure quality, with uniform 3D mechanical properties. The ProX SLS 6100 brings versatility to your applications, whether for functional prototyping or direct 3D production. Choose from industrial-grade, tough, impact and fatigue-resistant nylon 11 materials or strong, medical-grade, or flame-retardant capable nylon 12 thermoplastics, or filled nylons for advanced properties in terms of stiffness, temperature resistance, strength and surface finish.

Production Quality, Priced for Prototyping

Automated production tools, new air-cooled laser, remarkably high throughput, 95% material efficiency, and repeatability, combined with a competitive initial purchase price, deliver a 20% lower total cost of operations over similar printers. The material quality control (MQC) system provides automatic blending and recycling while providing transportation of material to the printer without manual intervention.

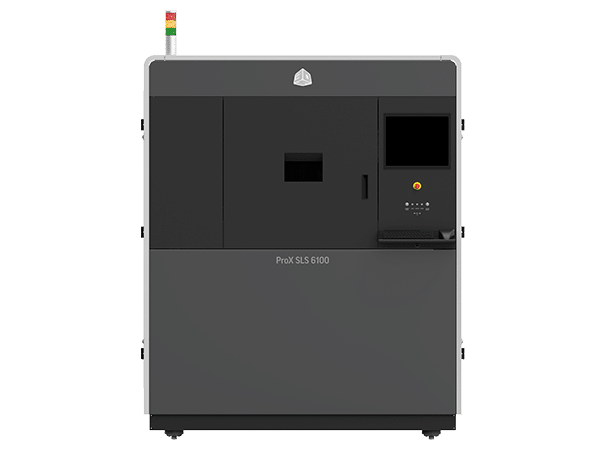

About this printer

-

APPLICATIONS

- Impact and temperature resistant durable parts

- Covers, housings, enclosures

- Jigs and fixtures

- Reduced weight production parts

- Knobs, handles and other dashboard/interior parts

- Parts with snap fits and living hinges

- Machinery components

- Complex duct work

-

BENEFITS

- Manufacture strong end-use parts and functional prototypes faster

- Easily print any design without using supports or post-processing

- Integrated solution with expert application support

- Full automation of material handling frees valuable resource

- Streamline your workflow with automated production tools

- Lower cost of ownership with high throughput and material efficiency

- Smoothest surface finish, highest resolution and edge definition of any SLS system

-

TECH SPECS

- Selective Laser Sintering (SLS) technology

- Max build envelope capacity (W x D x H): 15 x 13 x 18 in (381 x 330 x 460 mm)

- Broad range of production-grade nylon 11, nylon 12 and reinforced materials

- Consistent mechanical properties

- High production speed for its class of 2.7 l per hour

- Streamlined production control, including 3D Sprint™ integrated additive manufacturing software, fully automated powder handling and optional 3D Connect capability

- Automated 3D part nesting

- Maximized build volume and density